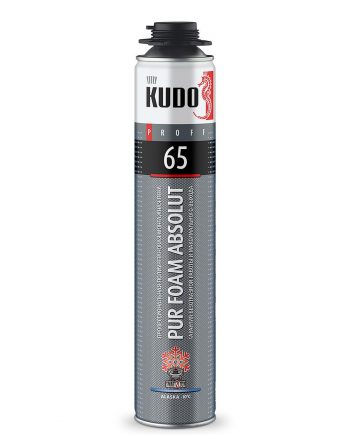

Professional summer PU foam sealant TREND 65

SKU: KUPT10S65

Intended for the installation of translucent structures, door blocks, and window sills, for mounting wall panels, sealing cracks and gaps, as well as other construction, finishing and installation works. The product is specially developed for a variety of professional sealing as well as thermal and sound insulation in construction.

It has high adhesion to most building materials, such as concrete, brickwork, plaster, wood, plastic, except for polyethylene, polypropylene and polytetrafluoroethylene (PTFE).

Offers a uniform, stable output and a perfect, fine-cell structure of the finished foam. Provides excellent thermal and sound insulation. Doesn’t cause structure deformation due to low expansion pressure.

This ingenious formulation comprising AFC® components allows for the use of a summer type foam sealant, when the can temperature is as low as 0°С.

Benefit

- Foam yield — up to 65 liters.*

- The length of a standard (3×3 cm) gap that can be filled with foam from a single can — 45 m*.

- Secondary expansion — no more than 25%.

- Tack-Free Time — up to 12 minutes*.

- First treatment time — up to 20 minutes*.

- Low curing pressure (max. 8 kPa TM 1009-2013).

- Сutting time — up to 25 minutes*.

- Stable dimensions in all temperature ranges of the bonding joint.

- No harmful solvents or additives.

- Environmentally friendly when cured.

* At a temperature of +23°C and a humidity of 50%.

Technical Information

| Content | 1000 ml |

|---|---|

| Type | Pu-foam |

| Units per box | 12 units |

| Foam type | Professional |

| Shelf life | 1 year |

| Seasonality | Summer |

How to use

- Make sure that the valve seat in the gun adapter is thoroughly cleaned before starting work. Otherwise, the valve may operate prematurely.

- For best results, apply the product at an ambient temperature from +5°C to +35°C and at a relative humidity not lower than 50%. Can temperature is from +5°C to +30°C.

- In order to obtain maximum foam yield and optimal physical and mechanical parameters, keep the can at a temperature of +18°C to +20°C for at least 10 hours before use.

- It is recommended to cover nearby surfaces with plastic film to do the work cleanly.

- Apply the foam to clean surfaces free of dust, dirt, grease, ice and frost.

- Mist with water the application surfaces before applying the foam.

- The operating position of the can is UPSIDE DOWN.

- Shake the can well at least 15 times in 30 seconds.

- Remove the protective cap from the can.

- Screw the gun onto the cross-shaped threaded adapter. Make sure the connection is tight.

- Fill gaps to 2/3 of their volume by applying the foam from bottom to top.

- Adjust the foam output with the gun screw.

- Shake the can from time to time while working.

- After application, mist the foam with water using a spray gun.

- Remove uncured foam with KUDO® FOAM & GUN CLEANER.

- Remove any excess foam with a knife after it has cured.

- Cured foam can be removed with KUDO® FOAM REMOVER.

- When the foam has cured completely (24-48 hours), it can be cut, plastered and painted.

- Protect the cured foam from UV exposure and atmospheric precipitation.

No questions about this product yet...