Private label manufacturing

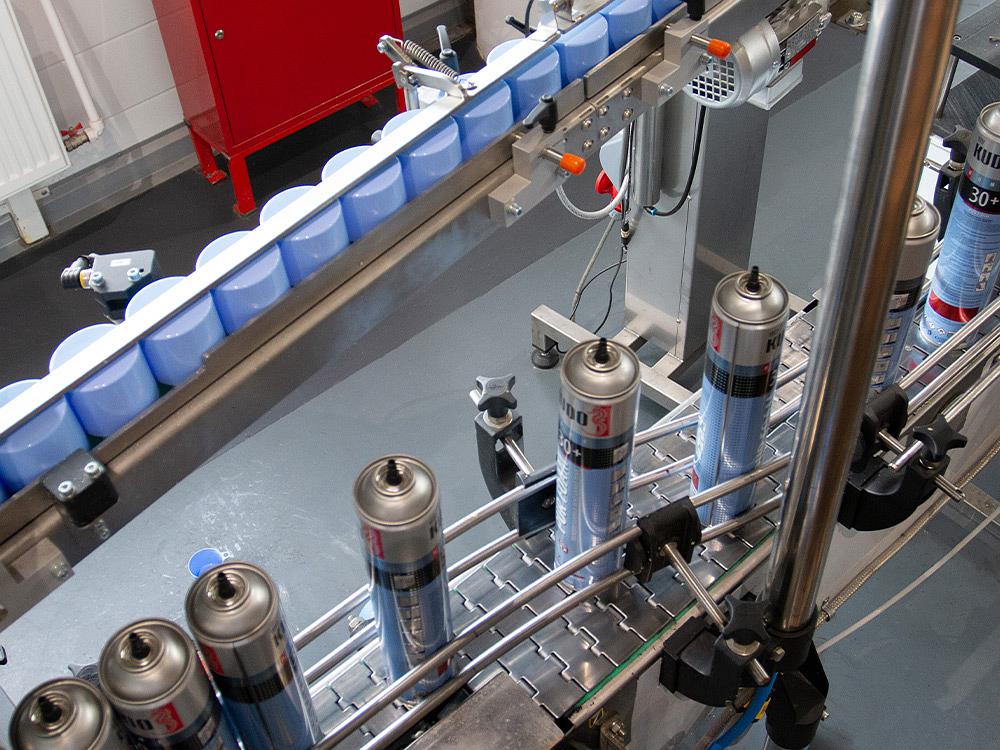

Contract Manufacturing using KUDO® Production Capacities.

Our Capabilities

Russian Technical Aerosols Group has been a leading manufacturer of technical aerosols, such as polyurethane sealing foam, sealants, adhesives, decorative and repair lacquers for household and professional use, auto detailing supplies, and other technical and industrial products for 20 years.

An extensive contract manufacturing partnership program, which using our manufacturing capabilities has produced many products for third-party companies, has been successfully implemented for many years.

We accept orders for contract production of sealing foam, lacquers, adhesives, sealants, and other technical products supplied in aerosol cans under your brand name.

Due to many years of experience in aerosols production and quality control at every production stage, we only offer our customers proven products, innovative developments, and the best technological solutions, customized to perform professional duties.

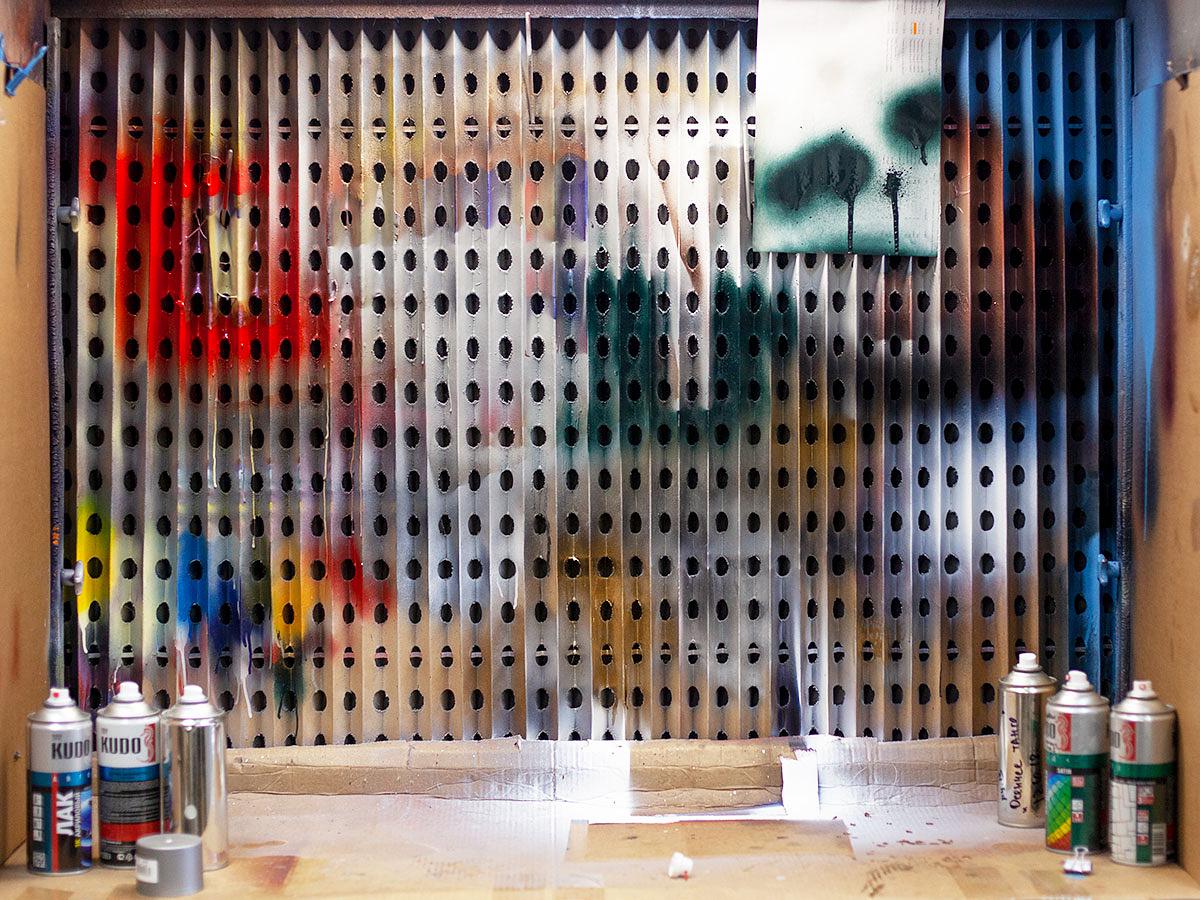

To introduce new products, we established our R&D Center, which is successfully operating. The Center is equipped with modern scientific and laboratory equipment. The R&D Center includes a Quality Control Laboratory, which inspects all raw materials and components supplied to the enterprise, and performs in-process monitoring at every production stage.

The plant with a total area of over 30,000 sq.m. is equipped with new high-yielding equipment that meets the European requirements for the safety of production and it has its own gas storage. The enterprise holds a license for operating explosion, fire and chemical hazard facilities.

A Quality Management System, certified in accordance with the requirements of the Russian Standard (GOST) R ISO 9001-2015 (ISO 9001:2015), has been introduced and successfully works at the enterprise.

A modern Class A warehouse complex with an advanced logistics system is operating on the premises of the plant.

Our Advantages

Selection of a ready-to-use formulation or the development of a custom product according to customer requirements

Products certification

Planning and procurement of raw materials

Product packaging

Conducting research and product testing

Development of the exterior design of aerosol cans

Contract filling

Delivery of finished goods

Obtaining related documentation

Lithography, label printing

Quality control of raw materials and components

Satisfied customer

We offer quality service and provide project

support at every stage of production

Unique KUDO® Technologies

Technology XPP®

(Xtra Perfomance Polymers)

A unique hybrid polymer technology providing both the maximum durability and the ultra-high performance of seals.

Ingenious Formula Composed of AFC®

(Advanced Freeze Control) Components

This ingenious formulation comprising AFC® components allows for the use of a summer type foam sealant, when the can temperature is as low as 0°С, all seasons –down to -5°С, and winter type – down to -10°С.

FCS® Technology

(Fireproof Control System)

A unique technology for controlling the fire resistance level of cured-foam insulation of various depths and widths.

SMART2LOCK®

The innovative Smart2Lock valve equipped with a 2-way lockout device.

Our Suppliers